Optical Fiber Electric Wire Copper Clad Aluminum Wire Electrical Cables and Wires CCA Wire

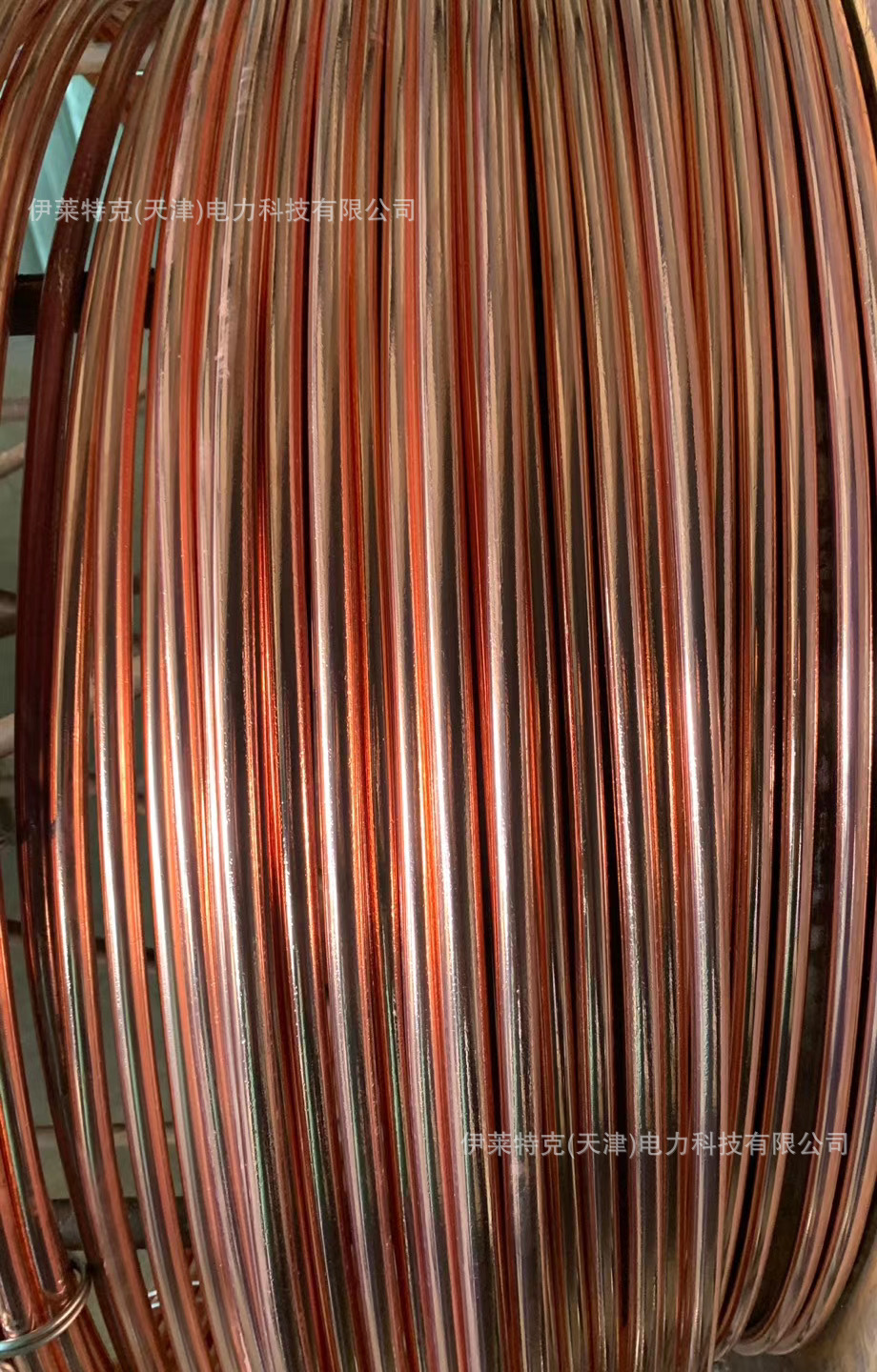

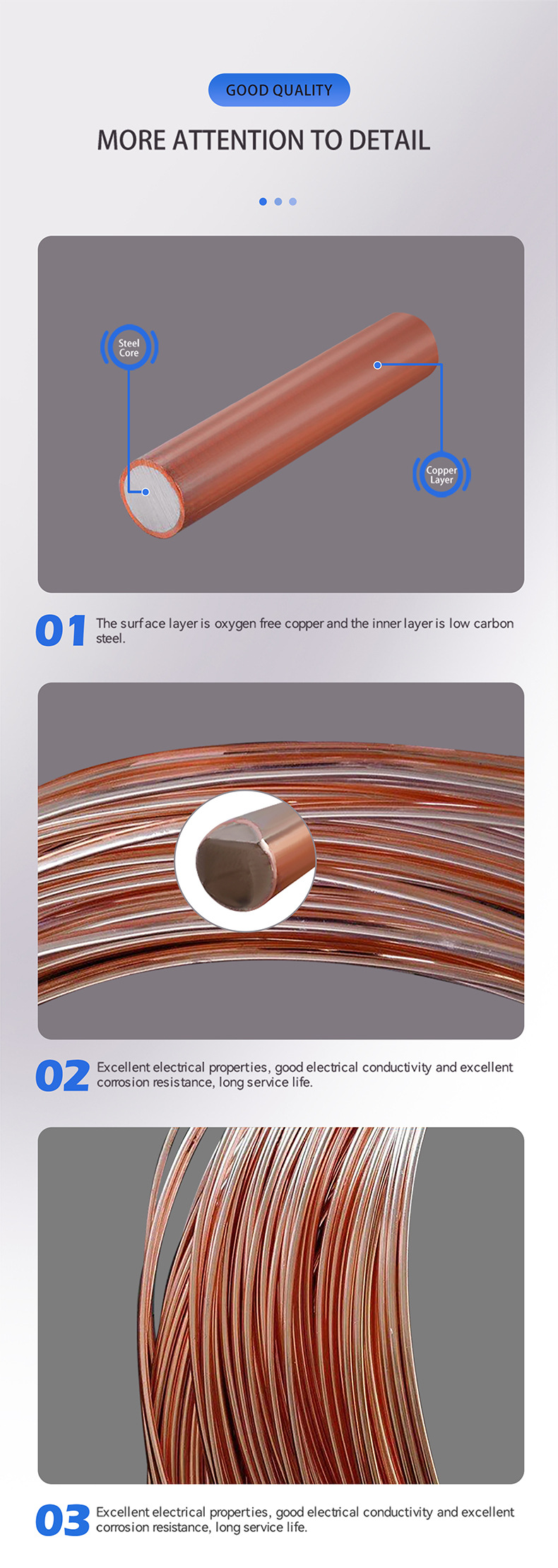

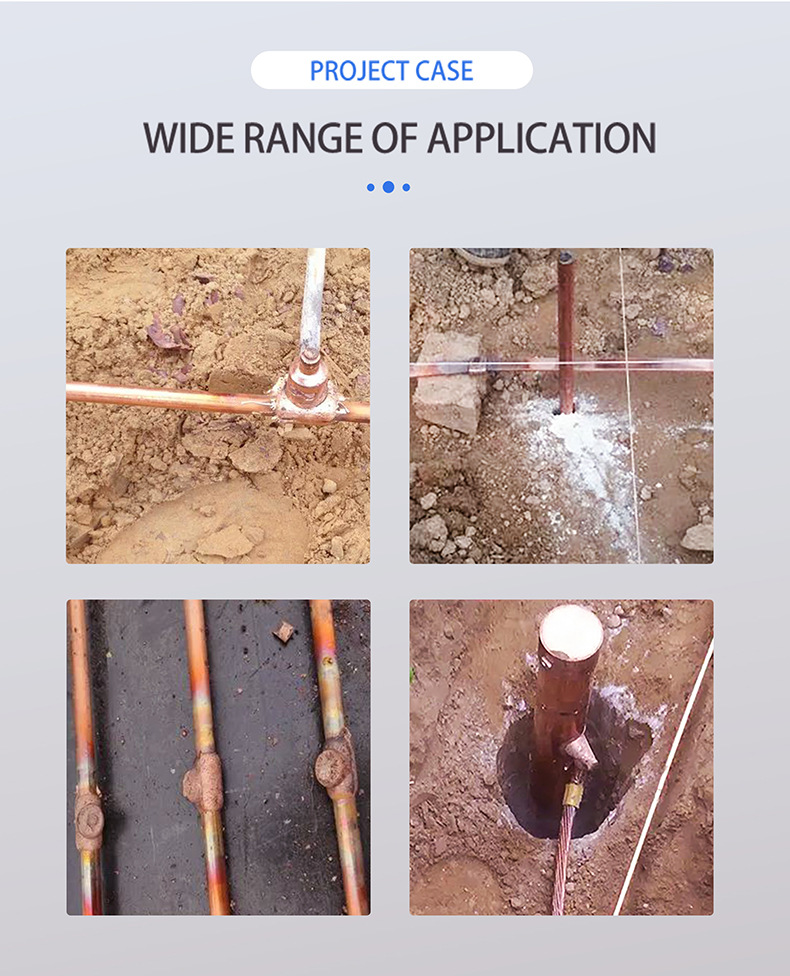

The copper-plated steel grounding wire material is based on foreign technology, electroplating electrolytic copper molecules with a content of 99.9% onto a low-carbon steel core, and becoming a new composite material of high molecular combination of copper and steel, which overcomes the traditional process. The galvanic cell reaction produced by the casing method solves the disadvantages of the purity of copper and the thickness of the copper layer in the hot-dip continuous casting process. During the construction process, the electroplated copper clad steel material can be bent freely and cut in length, and the surface copper layer will not peel off and fall off. Therefore, in recent years, electroplated copper clad steel has been widely recognized and praised by customers at home and abroad.

Manufacturing process characteristics: The electroplating production process is adopted to achieve a high degree of combination of copper and steel. The outer copper layer is composed of 99.99% electrolytic copper. It not only overcomes the shortcomings of the primary battery reaction in the casing process, but also solves the shortage of copper layer and the surface copper surface of the hot-dip continuous casting process. Other drawbacks.

Excellent anti-corrosion performance: The material indicates that the copper layer is thick and 99.99% of electrolytic copper molecules, the average thickness is more than 0.25mm, so the corrosion resistance is strong, and the service life is more than 50 years.

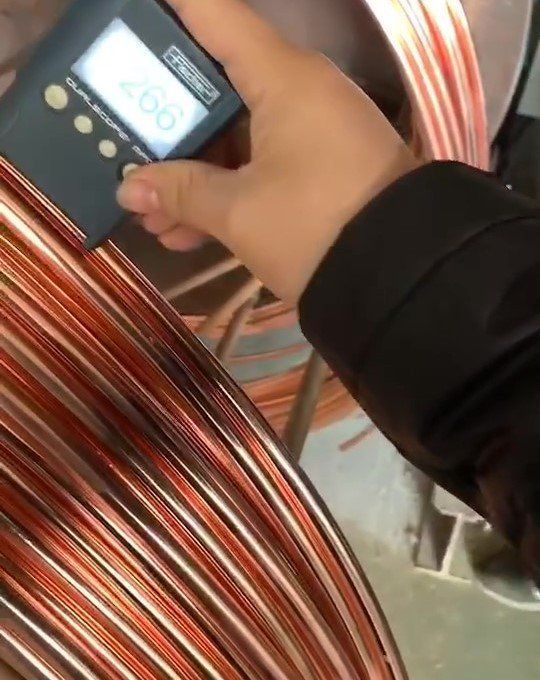

Better conductivity: Since the surface copper layer is composed of 99.99% electrolytic copper molecules, it has excellent electrical conductivity and its own resistance is much lower than that of conventional materials.